The Kinetic Plasma Cutting Reduced Processing Time by Almost 95%

We recently completed a kinetic plasma cutting time case study that demonstrates how dramatically KINETIC plasma cutting equipment can shorten manufacturing time. Thanks to integrated cutting, drilling, tapping and milling, KINETIC machines reduce the need to move materials from station to station and create a far more efficient manufacturing process. Over months and years, this level of speed and efficiency means dramatically increased capacity for your business, lower costs and higher profits.

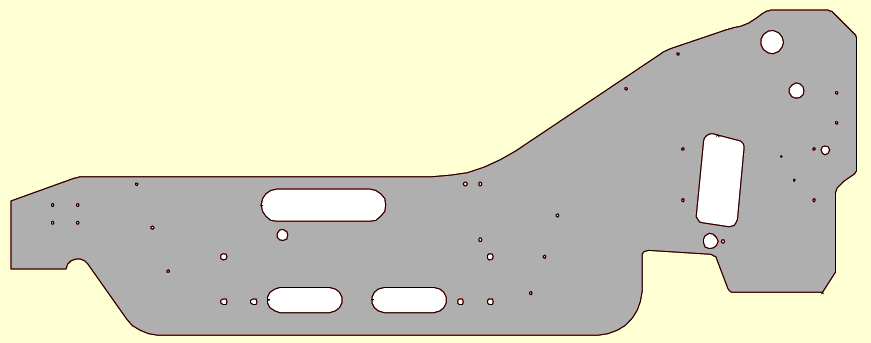

The Part

This particular part requires a variety of processes to complete: cutting, drilling and tapping. The accuracy of the hole locations must be within .005″, and the plasma torch must have a profile tolerance of less than .020″.

- 19 mm thick plate

- 11’ x 4.5’ in size

- 658 lbs.

THE EXISTING PROCESS

The existing manufacturing process includes loading the machine, cutting the parts, unloading and moving the plate, locating and loading fixtures, drilling, tapping and more. This process takes a total of 3.5 hours from start to finish.

THE NEW PROCESS

Using KINETIC plasma cutting equipment – which eliminates the need to move WIP from station to station – cutting, drilling and tapping processes take place on the same piece of equipment. The new process takes a total of 12.1 minutes from start to finish. That’s a 95% reduction in kinetic plasma cutting processing time!

REQUEST A TIME STUDY

We are happy to provide this same type of evaluation for your unique manufacturing needs. Simply contact us today and our manufacturing experts will answer all of your questions while determining the ROI for your particular parts and processes. We can usually turn around a time study within a few days if you can provide a DXF or DWG file and a PDF with specs and details.